EPDM Sponge | Anti Friction Gaskets

Description

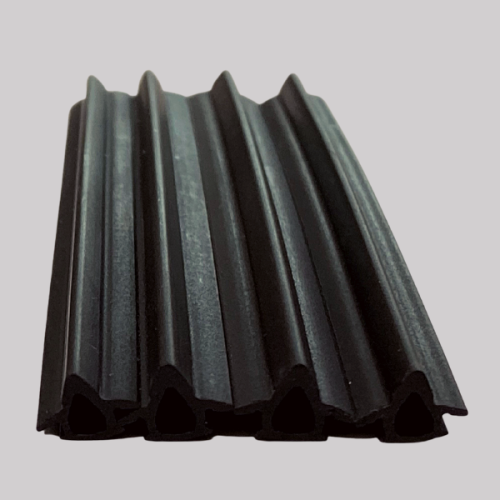

Product: EPDM Sponge | Anti Friction Gaskets

Category: Rubber Extrusion

We manufacture our EPDM sponge rubber gaskets from high quality cellular rubber sheets and rolls. These gaskets combine excellent weathering, UV as well as ozone resistance in a single package. This makes them ideal for use in a wide variety of outdoor sealing applications. EPDM sponge gaskets also feature a wide operating temperature range, with certain grades offering great high temperature resistance.

Another key feature of EPDM sponge rubber gaskets can be found in the materials acoustic, thermal and vibration dampening properties. EPDM sponge gaskets also feature good mechanical strength and abrasion resistant properties. This makes the gaskets suitable for use in a wide range of industrial as well as construction industries. While EPDM sponge gaskets do provide moderate water resistance, we would not recommend them for use in prolonged submersion applications.

Our EPDM sponge rubber gaskets are available with either a closed or open cell structure. Both formats offer similar properties in terms of operating temperature ranges and resistance. However, the cellular structure has a great effect on the sealing and mechanical properties of the gaskets. A closed cell material will generally be air and watertight as standard, requiring less compression in order to form a seal. These materials are generally less flexible and as a result, offer lower rates of compression. It is worth noting however, that a closed cell structure can burst if the material is placed under too greater compression. An open cell material will typically be more flexible and allow for greater rates of elongation. Despite being an open cell material, it is still possible to create an air and watertight seal through the use of compression.