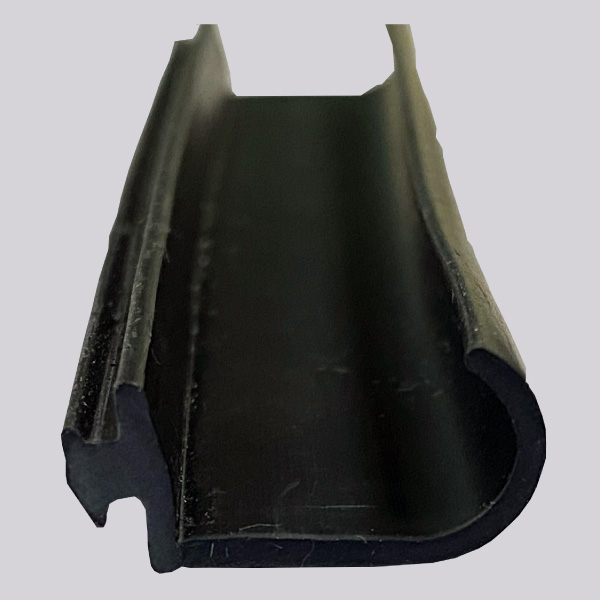

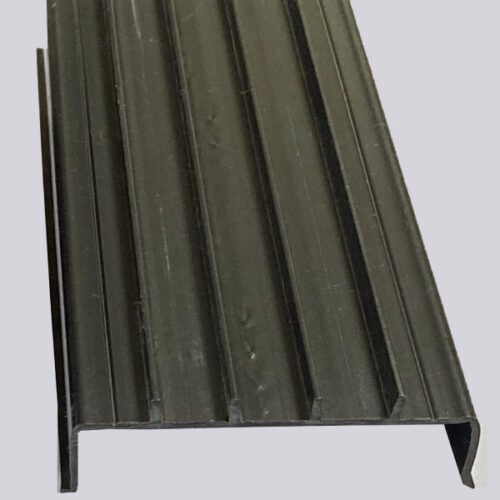

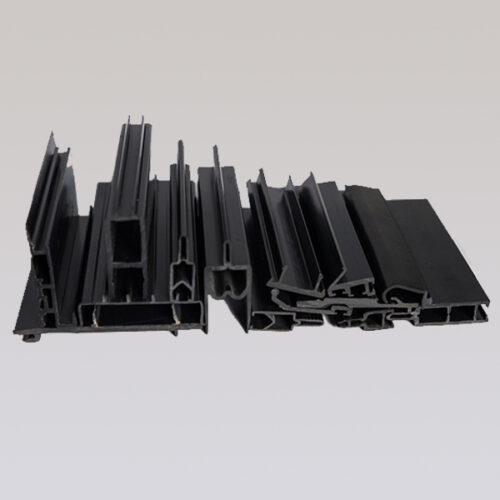

Plastics | TPE (Thermoplastic Elastomer)

Description

Product: TPE (Thermoplastic Elastomer)

Category: Plastic

Thermoplastic Elastomers (TPEs) are a class of polymers that, within their design limits, behave like thermoset rubber but that, above their melt or softening temperatures, are melt process able via thermoplastic processing methods and, unlike thermoset rubber, can be easily reprocessed and remolded. The ability to process these materials with thermoplastic methods allows for design and fabrication freedom that thermoset rubber does not offer. All TPEs are composed of crystalline and amorphous domains. Some are blends or alloys of crystalline and amorphous polymers, some are block co-polymers comprised of blocks of crystalline and amorphous domains along the same polymer chain.

It is the crystalline domains that act as the “heat-fugitive cross-links” that give TPEs their thermoplastic character and the amorphous domains that give them their elastomeric character the crystalline domains are typically referred to as the “hard” phase and the amorphous domains as the “soft” phase. While both phases contribute to the overall physical and mechanical properties of a TPE, some key properties may be associated with one phase or the other thereby guiding the selection or design of a TPE compound. TPV (Thermoplastic Vulcanized gasket) are compatible with structural and weather silicone sealants.

Due to its property of good electrical resistivity, it is used in place of high energy electrical cables such as smelters and composite joints. Various colors can be produced based on the customer’s requirement.