Rubber Extrusion | Co Extrusion

Description

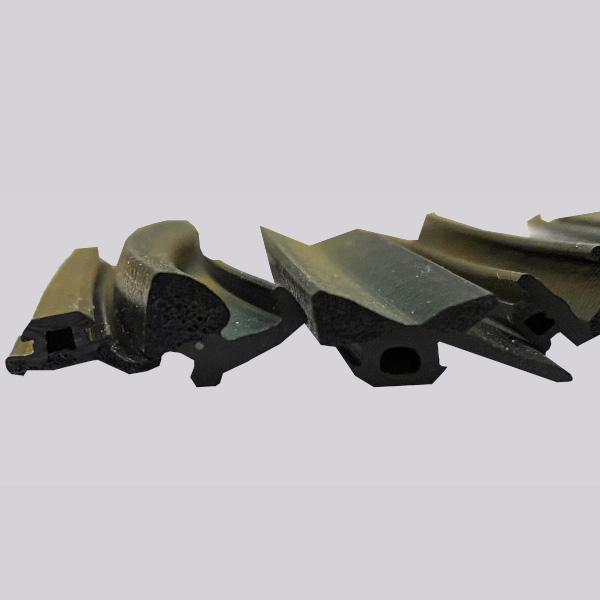

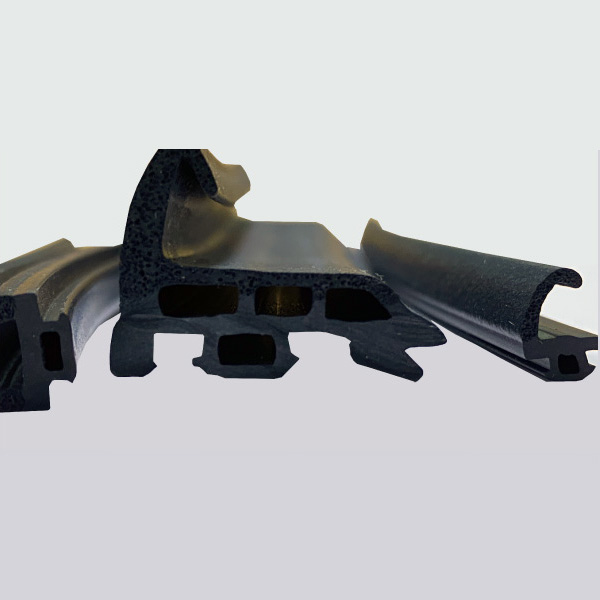

Product: Co Extrusion

Category: Rubber Extrusion

Dual durometer extrusions can serve a variety of purposes. Most often, the harder material serves as means of attachment, and the softer compound completes the seal. Sometimes, however, co-extruding polymers is done for cosmetic purposes.

There are many ways to get creative when designing a seal— using multi-color, multi-durometer, notches, holes and PSAs. You can mix and match, or, put them all into one package. Click here to send an email or call us with your next project. EPDM

Coextruded products combine two or more materials through a single die with two or more cavities arranged so that the extrusions merge and weld together into one structure. GRI co-extrudes EPDM and EPDM closed cellular sponge into a variety of shapes to form a consistent cross section. As the physical properties of both the materials are different, close observation and perfectly homogenized compound is essential for the extrusion. As both the compounds have different viscosity and curing temperature, the process parameters will differ as compared to single durometer extrusion. Most often, the harder material serves as means of attachment, and the softer compound completes the seal.

The tooling too is a complex structure where in two different dies one for the harder material and one for the softer material are assembled in such a way that they act as one single die from which the desired geometry of the profile is extruded. The control parameters include the density and tolerance of both materials as individual and geometry as a whole part.