Request for Quotation

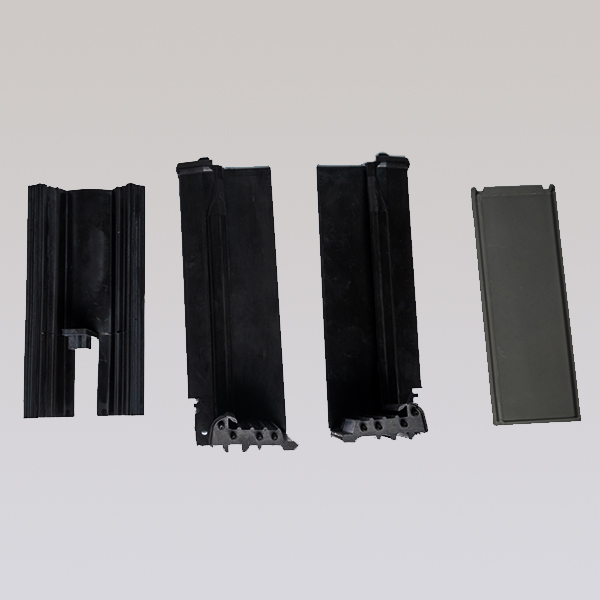

- MOULDING

We have built our manufacturing process on the intent that every customer’s need is unique. With our in-house molding capabilities, along with our engineering expertise, we can work with you to ensure that your parts are produced with quality, mold reliability and performance in mind.

Molded Details are an advanced science of molding rubber or plastic material around or conjoined to a polymer extrusion, metal or other component. Proper tooling enables this complex process to work for tight tolerance requirements. This procedure requires the selection of compatible materials in order to achieve superior physical and chemical bonding.

There are two basic types of molding processes used for molded details: compression and transfer.

- PRODUCTS

- Extruded dense EPDM Profiles

- Sponge EPDM Profiles

- Neoprene, SBR Profiles

- Silicone Profiles

- Co-Extrusion profiles

- Silicone compatible EPDM

- TPE Profiles

- LDPE & HDPE Profiles

- Vulcanized Frames

- Moulded corners & Moulded parts

- Setting blocks

- Flame Retardant profiles

- Self Adhesive profile

- Refrigerated van profiles

- Container Seals

- EPDM Façade sealing Membrane

- Rigid PVC Profiles

- D-Fenders, Wall Guards, Column Guards.

- O-Rings & Gaskets.